The Functional Science of Grease-Resistant Barriers

Hamburger wrapping paper serves a much more technical purpose than simply acting as a decorative sleeve. At its core, the primary function is grease resistance. High-quality wraps are treated with food-safe coatings or manufactured using dense, non-porous fibers that prevent oils and sauces from seeping through to the consumer's hands. This barrier is essential for maintaining the structural integrity of the burger itself, as it prevents the bun from absorbing external moisture while simultaneously trapping heat to keep the patty at an optimal serving temperature during transit.

Thermal Retention and Moisture Control

A critical challenge in food packaging is the balance between heat retention and steam management. If a wrap is too occlusive, the steam from the hot meat will settle back onto the bun, making it soggy. Premium hamburger wrapping papers often utilize a breathable parchment or a foil-laminate hybrid that allows just enough moisture to escape while reflecting heat back toward the center of the product. This ensures that the texture of the bread remains light and airy, even if the meal is not consumed immediately after assembly.

Comparing Common Material Types

Choosing the right material depends on the specific needs of the menu item, such as the fat content of the beef or the presence of heavy condiments. Modern restaurants typically choose between three main categories of wrapping materials, each offering distinct advantages in terms of cost, performance, and aesthetic appeal.

| Material Type | Key Features | Best Use Case |

| Greaseproof Paper | Non-stick, breathable, and economical. | Classic cheeseburgers and dry sandwiches. |

| Foil-Laminated Wrap | Superior heat retention and dead-fold memory. | Takeout orders and high-temperature patties. |

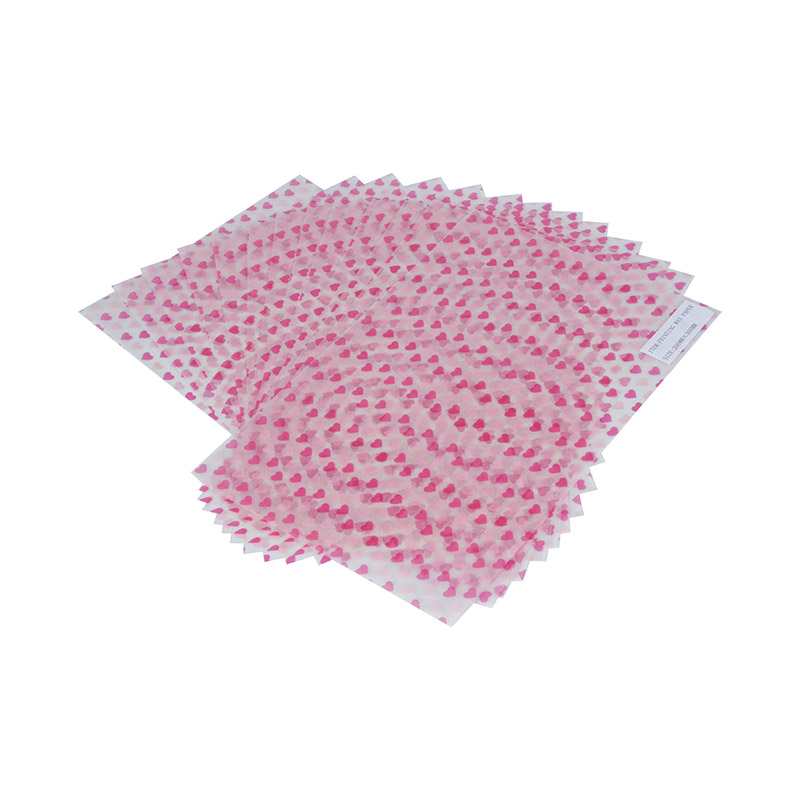

| Wax-Coated Tissue | Waterproof and highly flexible. | Cold sandwiches or lining plastic baskets. |

Sustainability and Eco-Friendly Innovations

As consumer awareness regarding environmental impact grows, the demand for sustainable hamburger wrapping paper has surged. Traditional plastic-lined wraps are being replaced by biodegradable and compostable alternatives that do not sacrifice performance. These innovations focus on using plant-based waxes (such as soy or carnauba) and FSC-certified paper pulp to ensure that the packaging can be disposed of in organic waste streams rather than contributing to landfill growth.

- PFAS-Free Coatings: Eliminating "forever chemicals" while maintaining grease resistance.

- Unbleached Kraft Paper: Reducing chemical use in the manufacturing process for a rustic, natural look.

- Water-Based Inks: Utilizing soy or vegetable-based inks for custom branding to ensure the paper remains compostable.

Branding and Marketing Value

Hamburger wrapping paper is a powerful marketing tool that provides a direct touchpoint with the customer. Custom printing allows a brand to communicate its personality through logos, social media handles, or QR codes. Beyond aesthetics, the "unboxing" experience of a neatly wrapped burger creates a perception of quality and hygiene. A crisp, well-folded wrap signals to the customer that the food was prepared with care and attention to detail, reinforcing brand loyalty before the first bite is even taken.

English

English русский

русский