The humble sandwich, a cornerstone of global cuisine, demands packaging that is both functional and a powerful marketing tool. In the bustling world of grab-and-go food service, the Printed Sandwich Wrap has emerged as a vital component, transcending its basic protective function to become an integral part of brand identity and food safety compliance. This article explores the significance of custom-printed wraps, their benefits, and the evolving trends in their design and material science.

Beyond Protection: Branding and Consumer Connection

A primary function of any food packaging is to keep the product fresh and safe. The Printed Sandwich Wrap excels here, offering a grease-resistant barrier that maintains the sandwich’s integrity while keeping hands clean. However, the true value of custom printing lies in the marketing opportunity it presents.

In a highly competitive market, brand recognition is paramount. A high-quality, attractively designed Printed Sandwich Wrap serves as a silent salesperson. It ensures the brand’s logo, colors, and message are visible right up to the point of consumption, reinforcing brand recall and loyalty. This immediate visual connection is especially critical for cafes, delis, and food trucks that rely on rapid customer turnover and consistent visual presentation. By incorporating QR codes, social media handles, or promotional messages, the wrap can also transform into an interactive piece of marketing collateral, driving engagement long after the purchase.

Material Matters: Sustainability and Safety Standards

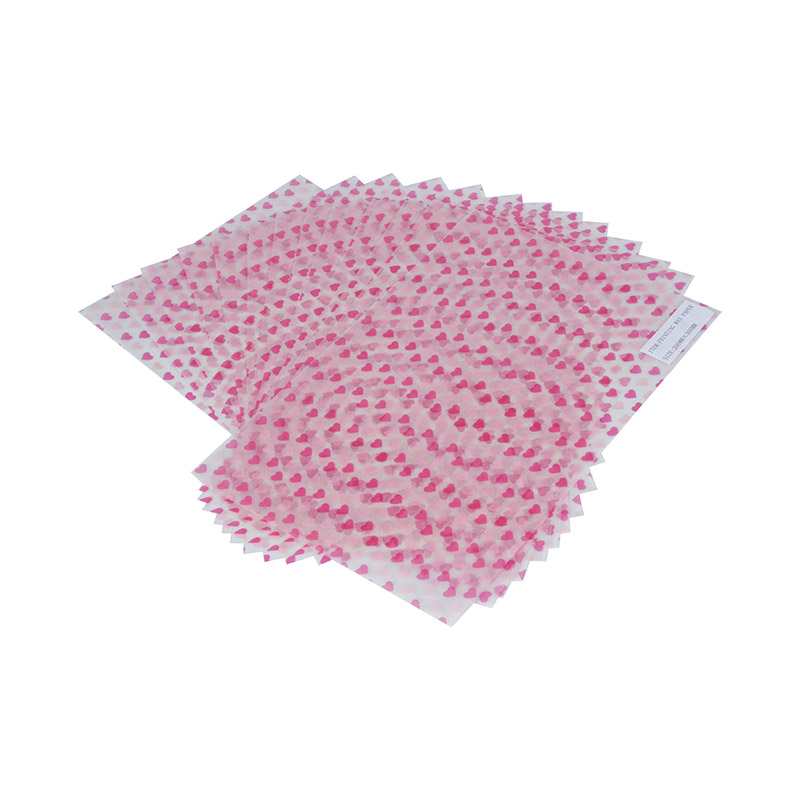

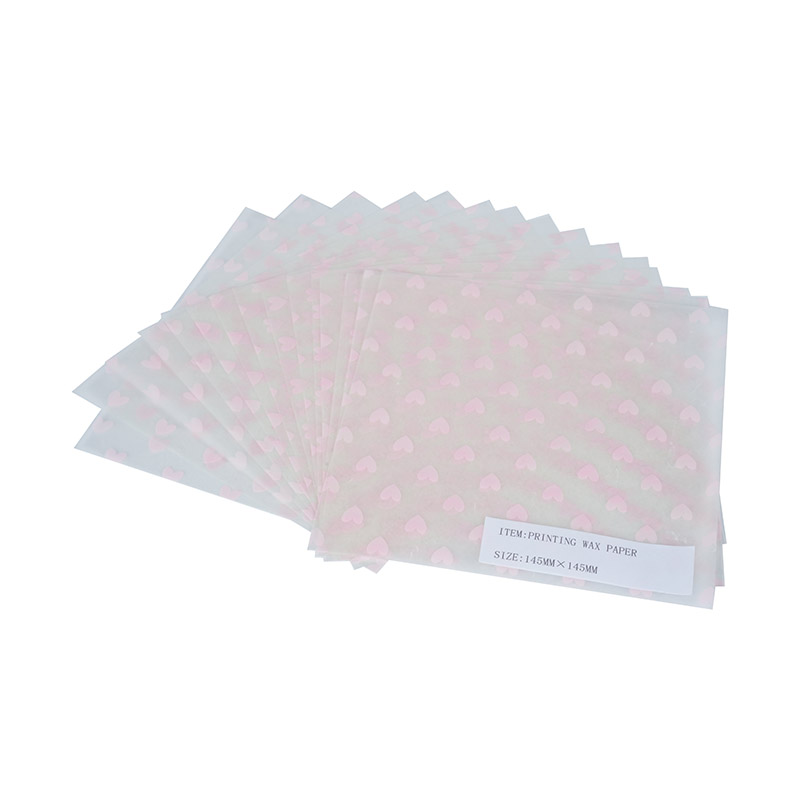

The selection of material for a Printed Sandwich Wrap is a critical decision, balancing cost, functionality, and environmental responsibility. Traditionally, wraps have been made from food-grade parchment or wax-coated paper, chosen for their inherent grease and moisture resistance.

Today, there is a strong industry shift toward sustainable options. Food service providers are increasingly opting for wraps made from:

- Recycled Content: Papers with a percentage of post-consumer waste.

- Compostable or Biodegradable Materials: Wraps treated with coatings that break down naturally, aligning with global efforts to reduce landfill waste.

- FSC-Certified Paper: Sourced from responsibly managed forests, assuring customers of a commitment to environmental stewardship.

Furthermore, all materials and inks used in the creation of the Printed Sandwich Wrap must adhere to stringent food-safety regulations (such as FDA or EU standards). The printing process uses non-toxic, food-grade inks to ensure there is no migration of chemicals to the food product, guaranteeing consumer safety.

Design and Utility: Maximizing Impact

Effective design for a Printed Sandwich Wrap hinges on a synergy between aesthetics and practical utility. Designers must consider the varying sizes and shapes of sandwiches, ensuring the wrap offers sufficient coverage without excessive waste.

Key design considerations include:

- Print Coverage: While full coverage can be visually impactful, strategic use of negative space can be more cost-effective and aesthetically pleasing, drawing attention to key branding elements.

- Color Palette: Colors should be vibrant and consistent with the brand’s identity, but also practical for the printing process, often favoring a two- or three-color spot-color approach for efficiency.

- Clarity of Information: Essential information, like allergen warnings or ingredient lists, can be discretely integrated into the wrap’s design, adding value beyond just branding.

In conclusion, the evolution of the Printed Sandwich Wrap demonstrates how a seemingly utilitarian item can become a powerful strategic asset. By prioritizing sustainable materials, thoughtful design, and clear branding, food businesses can leverage this essential packaging component to enhance customer experience, reinforce brand messaging, and adhere to the highest standards of food safety.

English

English русский

русский