The simple candy wrap is much more than just a colorful piece of packaging. It's a critical component of a candy's journey from the factory to your hand, serving a dual purpose: it protects the product and serves as a canvas for branding and marketing. The material used for a candy wrap is chosen based on the candy's properties, shelf life requirements, and the desired consumer experience.

Foil Wrappers

Foil wrappers, typically made from aluminum, are a classic choice for many types of chocolate. The material’s malleability allows it to be tightly molded around a product, like a Hershey's Kiss, providing an airtight seal that helps maintain freshness and prevent oxidation. Its reflective quality also helps to deflect heat and light, which is crucial for preventing chocolate from melting. This type of candy wrap is not only functional but also gives a premium, high-quality feel to the product.

Cellophane and Polypropylene Wrappers

Cellophane and polypropylene (plastic film) are a common sight on hard candies, lollipops, and taffy. These materials are known for their transparency, which allows the product's color and shape to be seen, making it visually appealing. They are highly resistant to moisture and oxygen, which is essential for preserving the crispness and flavor of hard candies. Polypropylene is a more modern alternative to cellophane, offering better durability and a crinkly texture that is synonymous with the sound of unwrapping a treat.

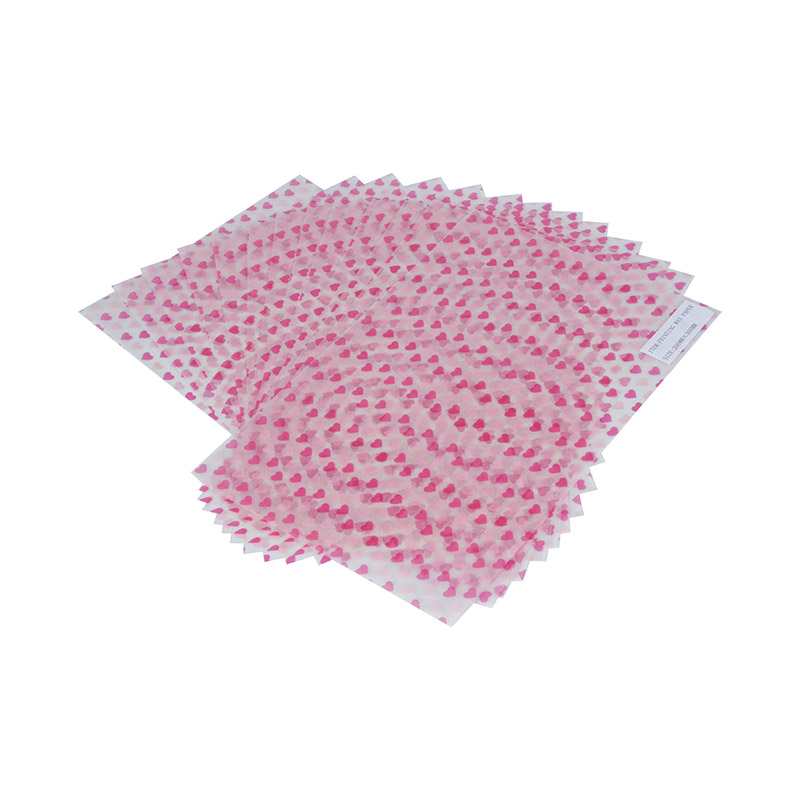

Waxed Paper Wrappers

Waxed paper has been a staple in the candy industry for generations, particularly for chewy candies like caramels and taffy. The wax coating provides a non-stick surface, which prevents the sticky candy from adhering to the candy wrap itself. This makes the candy easy to unwrap and eat. While not airtight, waxed paper is effective at keeping the candy fresh for a short period. It also offers a traditional, rustic aesthetic that evokes a sense of nostalgia.

Twist Wraps

Twist wraps are a simple, effective solution for wrapping small, individual candies like hard candy drops or bonbons. The wrapping material, often cellophane or waxed paper, is twisted at both ends to secure the product. This method is incredibly efficient for high-volume production and allows for quick and easy unwrapping. While it doesn’t provide an airtight seal, it is sufficient for products with a long shelf life that are less susceptible to moisture and air.

Flow Wraps and Fin Seal Wraps

For products like candy bars, snack bars, and individually packaged chocolates, a flow wrap or fin seal wrap is the preferred method. This automated process involves forming a continuous tube of film around the product and then sealing it with a series of heated rollers. The result is a sealed packet with a fin-shaped seal along the back and crimped seals at both ends. This type of candy wrap provides an excellent barrier against moisture, air, and light, making it ideal for products with a longer shelf life. It also offers a large, flat surface for printing high-quality graphics and nutritional information.

Choosing the right type of candy wrap is a strategic decision that balances product preservation, aesthetic appeal, and production efficiency. Each material and method tells a story about the candy inside, creating an experience that begins long before the first bite.

English

English русский

русский