Understanding Sandwich Wrap Paper and Its Importance Sandwich wrap paper is a fundamental component in the food service industry, designed to protect,...

READ MOREAll

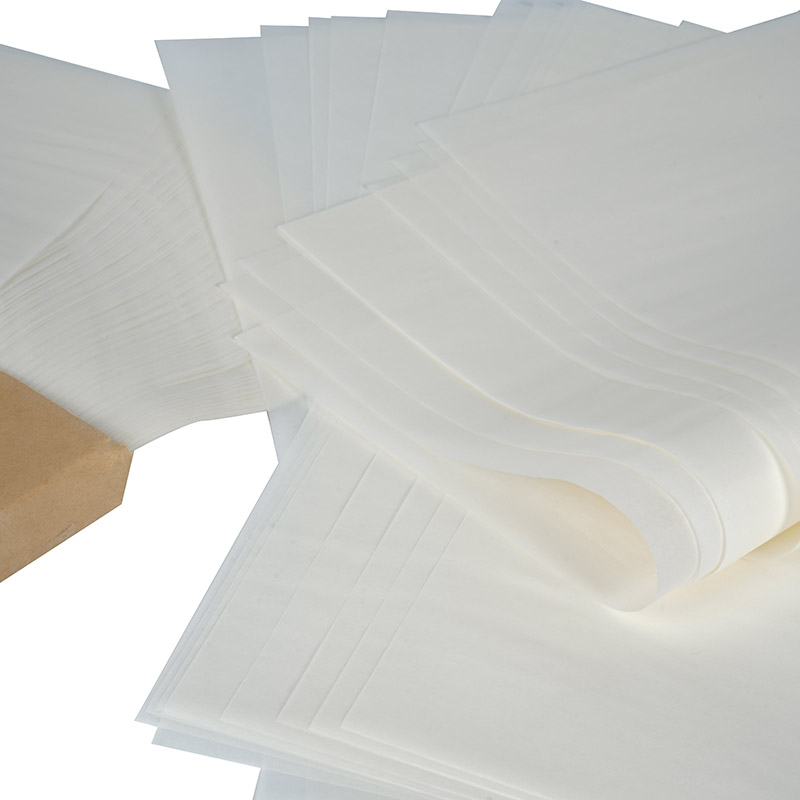

Baking Paper

Greaseproof Paper

Wax Paper

Parchment Paper

Cooking Sheet Paper

Steaming Paper

Hamburger Wrap

Sandwich Wrap

Pan Liner

Candy Wrap

Air Fryer Paper

Pulp Style Virgin Pulping Type Chemical-Mechanical Pulp Coating Material silicone Compatible Printin...

Pulp Style Virgin Pulping Type Chemical-Mechanical Pulp Coating Material silicone Compatible Printin...

Pulp Style Virgin Pulping Type Chemical-Mechanical Pulp Coating Material silicone Compatible Printin...

Pulp Style Virgin Pulping Type Chemical-Mechanical Pulp Coating Material silicone Compatible Printin...

Understanding Sandwich Wrap Paper and Its Importance Sandwich wrap paper is a fundamental component in the food service industry, designed to protect,...

READ MOREThe Functional Science of Grease-Resistant Barriers Hamburger wrapping paper serves a much more technical purpose than simply acting as a decorative s...

READ MOREThe Essential Role of Steamer Paper in Modern Cooking Steamer paper, often referred to as perforated parchment liners, serves as a critical barrier be...

READ MOREThe Critical Role of Steamer Paper in Modern Cooking Steamer paper, often referred to as perforated parchment paper, is an indispensable tool for anyo...

READ MOREWhat is the environmental impact of using virgin wood pulp in Cooking Sheet Paper?

Cooking sheet paper, an essential tool in kitchens worldwide for its non-stick and heat-resistant properties, is often made from virgin wood pulp. While highly functional, the production of cooking sheet paper from virgin wood pulp carries significant environmental implications. This article delves into the environmental impact of using virgin wood pulp for cooking sheet paper, highlighting key issues and considerations.

Primary Forests: Harvesting trees for virgin wood pulp often involves clearing primary forests. These forests are vital habitats for numerous plant and animal species, and their destruction can lead to biodiversity loss and disrupt local ecosystems.

Impact on Indigenous Communities: Deforestation for pulpwood plantations can displace indigenous communities who depend on forests for their livelihoods and cultural practices.

Greenhouse Gas Emissions: The production of virgin wood pulp and cooking sheet paper involves energy-intensive processes such as logging, transportation, pulping, bleaching, and papermaking. These processes contribute to greenhouse gas emissions, exacerbating climate change.

Carbon Sequestration: Deforestation reduces the capacity of forests to sequester carbon dioxide, further intensifying the carbon footprint of virgin wood pulp production.

Water Consumption: Pulp and paper manufacturing require large volumes of water for processing and cooling purposes. Water withdrawals can impact local water sources and ecosystems, especially in regions experiencing water scarcity.

Chemical Pollution: The pulping and bleaching processes often involve the use of chemicals such as chlorine and sodium hydroxide, which can pollute waterways and harm aquatic life if not properly managed.

Loss of Soil Fertility: Intensive forestry practices and logging can lead to soil erosion and degradation, reducing soil fertility and affecting agricultural productivity in surrounding areas.

Sedimentation: Soil erosion from deforested areas can lead to sedimentation in rivers and streams, impacting aquatic habitats and water quality.

Sustainability Practices and Mitigation Strategies

Forest Stewardship Council (FSC) Certification: FSC-certified virgin wood pulp is sourced from responsibly managed forests that adhere to strict environmental and social standards. Certification ensures sustainable forestry practices, biodiversity conservation, and community engagement.

Programme for the Endorsement of Forest Certification (PEFC): Similar to FSC, PEFC promotes sustainable forest management and responsible sourcing practices.

Energy Efficiency: Implementing energy-efficient technologies and practices in pulp and paper mills can reduce greenhouse gas emissions and overall energy consumption.

Water Management: Investing in water recycling systems and reducing water use in manufacturing processes can mitigate the environmental impact on water resources.

Recycled Fibers: Utilizing recycled paper fibers reduces the demand for virgin wood pulp and promotes a circular economy by extending the life cycle of paper products.

Non-Wood Fibers: Exploring alternative fibers such as bamboo, hemp, and agricultural residues offers renewable and potentially more sustainable alternatives to virgin wood pulp.

Lifecycle Assessments (LCA): Conducting LCAs to evaluate the environmental impacts of cooking sheet paper production can identify hotspots and inform strategies for continuous improvement.

Transparency and Reporting: Providing stakeholders with transparent information on sourcing practices, environmental performance, and compliance with sustainability standards fosters accountability and trust.

Environmental Impact Awareness: Raising awareness among consumers about the environmental consequences of virgin wood pulp production encourages informed purchasing decisions.

Promoting Sustainable Alternatives: Highlighting eco-friendly alternatives like recycled paper and non-wood fibers empowers consumers to choose products with lower environmental footprints.

Market Trends: Growing consumer preferences for sustainable and eco-friendly products are driving market demand for cooking sheet paper that prioritizes environmental stewardship.

Industry Response: Manufacturers responding to consumer demand by adopting sustainable practices and offering certified products demonstrate industry leadership in environmental responsibility.

How to manage energy waste generated during the production of Cooking Sheet Paper?

Managing energy waste during the production of cooking sheet paper involves several strategies:

Process Optimization

Efficient Equipment: Use energy-efficient machinery and technologies that reduce energy consumption.

Heat Recovery: Capture and reuse heat from processes such as drying and coating to reduce the need for additional heating.

Energy Audits

Regular Audits: Conduct energy audits to identify and rectify inefficiencies in the production process.

Real-time Monitoring: Implement systems to monitor energy usage and quickly address waste.

Waste Reduction

Material Efficiency: Optimize raw material use to minimize waste and reduce energy required for production.

Recycling: Recycle waste heat, water, and materials within the production process.

Renewable Energy

Green Energy: Utilize renewable energy sources like solar or wind to power production facilities.

Energy Storage: Implement energy storage systems to manage and balance energy supply and demand.

Employee Training

Awareness Programs: Train employees on energy-saving practices and encourage a culture of energy efficiency.

By integrating these strategies, energy waste in cooking sheet paper production can be significantly reduced, leading to cost savings and environmental benefits.