In today’s fast-paced food industry, greaseproof paper—also called oil-proof paper or non-stick parchment paper—has become a cornerstone of smart, hygienic food packaging. Its ability to resist oil, moisture, and heat makes it an ideal solution for both foodservice professionals and eco-conscious consumers.

Understanding Greaseproof Paper

Greaseproof paper is made through a process that creates a dense, smooth surface, making it resistant to oil and grease. This feature sets it apart from regular paper, which absorbs oils and quickly degrades. Whether it’s for lining food containers or wrapping snacks, greaseproof paper maintains structural integrity and cleanliness.

A Key Player in Food Safety and Presentation

Oil-resistant paper plays a dual role: ensuring hygiene and enhancing presentation. Greasy foods like pizza, fried snacks, and baked goods can easily ruin their packaging without a proper barrier. With greaseproof wrapping, the packaging stays neat, preventing oil stains and offering a better customer experience.

Additionally, non-stick baking paper ensures that food does not cling to trays or pans, eliminating the need for cooking sprays or additional fats. This not only supports healthier cooking but also reduces waste and cleanup time.

Versatility in Application

The versatility of greaseproof paper is unmatched. It’s widely used for:

Bakery wrapping: Keeps pastries and breads fresh and dry.

Fast food packaging: Ideal for burgers, fries, and wraps.

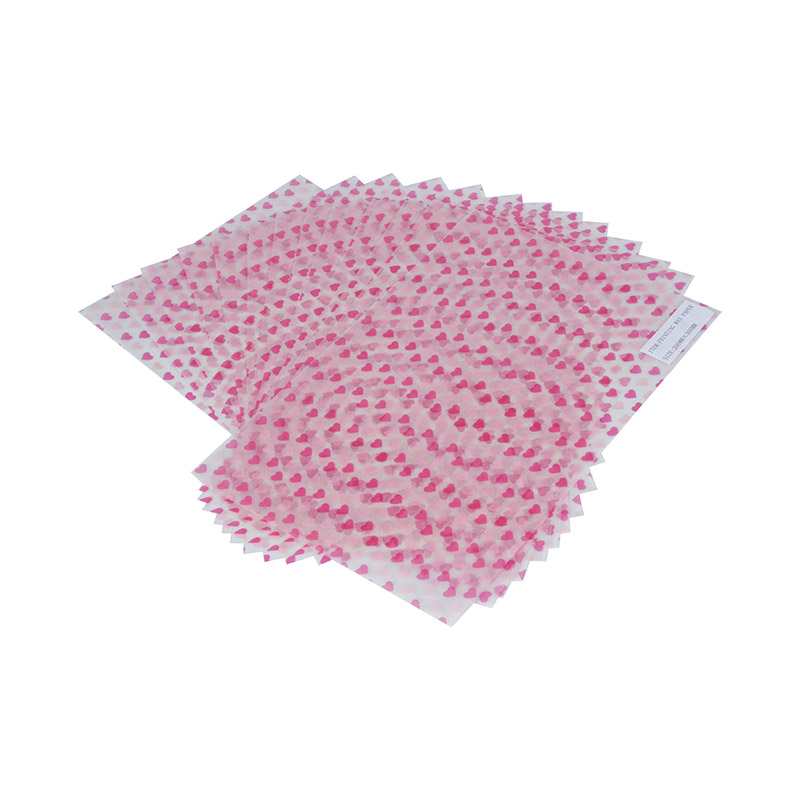

Confectionery: Protects chocolates and sweets from melting and sticking.

Takeaway liners: Maintains cleanliness inside food boxes and trays.

In addition, it’s often used in creative DIY and gift-wrapping projects, thanks to its smooth texture and elegant look.

How to Select the Right Greaseproof Paper

When choosing a greaseproof paper for business or home use, consider the following:

Thickness (GSM): Higher GSM papers provide better resistance and durability.

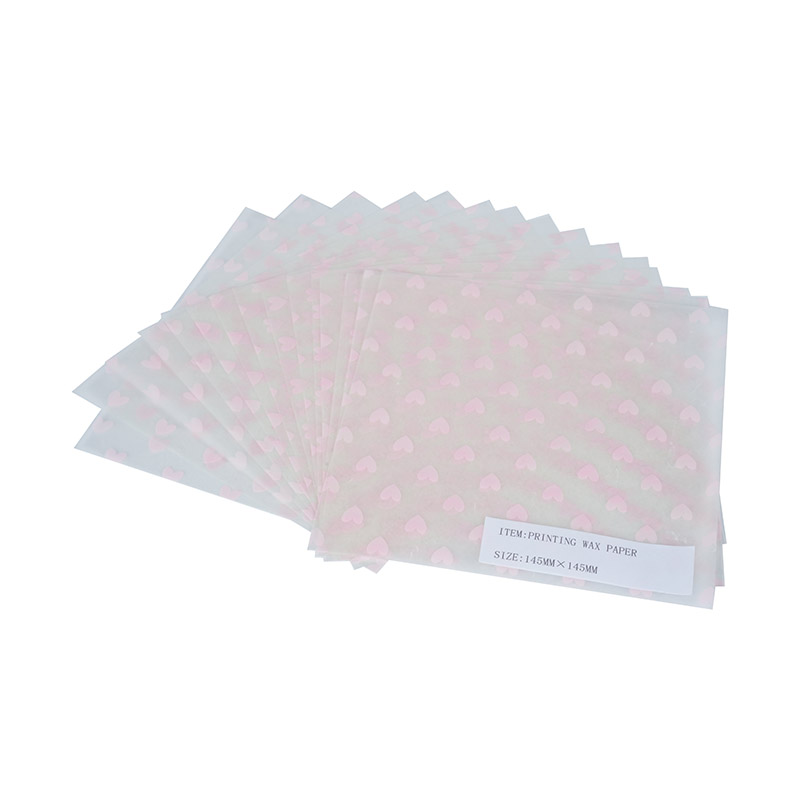

Coating: Some papers are coated with silicone or wax for extra protection.

Size and format: Sheets, rolls, or pre-cut liners are available based on specific needs.

Certifications: Always check for food-grade certifications and safety compliance.

English

English русский

русский