Understanding Sandwich Wrap Paper and Its Importance Sandwich wrap paper is a fundamental component in the food service industry, designed to protect,...

READ MOREAll

Baking Paper

Greaseproof Paper

Wax Paper

Parchment Paper

Cooking Sheet Paper

Steaming Paper

Hamburger Wrap

Sandwich Wrap

Pan Liner

Candy Wrap

Air Fryer Paper

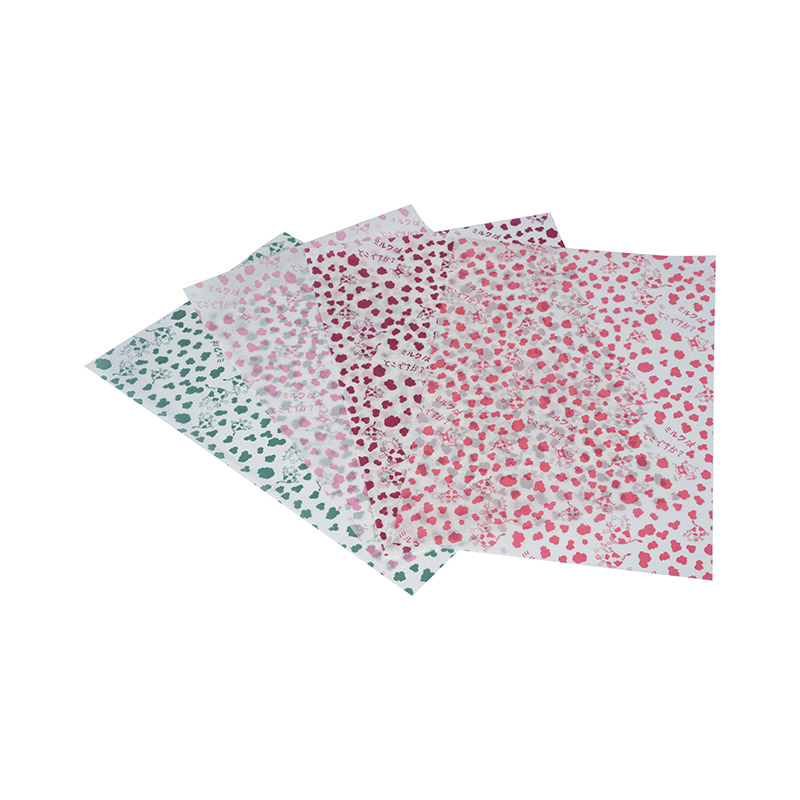

Brand Name: YISAKA Compatible Printing Letterpress printing Feature Greaseproof Packing Sheet Materi...

Brand Name: YISAKA Compatible Printing Letterpress printing Feature Greaseproof Packing Sheet Materi...

Brand Name: YISAKA Compatible Printing Letterpress printing Feature Greaseproof Packing Sheet Materi...

Understanding Sandwich Wrap Paper and Its Importance Sandwich wrap paper is a fundamental component in the food service industry, designed to protect,...

READ MOREThe Functional Science of Grease-Resistant Barriers Hamburger wrapping paper serves a much more technical purpose than simply acting as a decorative s...

READ MOREThe Essential Role of Steamer Paper in Modern Cooking Steamer paper, often referred to as perforated parchment liners, serves as a critical barrier be...

READ MOREThe Critical Role of Steamer Paper in Modern Cooking Steamer paper, often referred to as perforated parchment paper, is an indispensable tool for anyo...

READ MOREHow biodegradable and compostable materials can enhance the environmental impact of sandwich wraps?

In today's environmentally conscious world, the demand for sustainable packaging solutions is on the rise. Sandwich wraps, essential for food containment and preservation, are increasingly adopting biodegradable and compostable materials to enhance their environmental performance. This article explores the benefits of biodegradable and compostable materials in sandwich wrap packaging and their positive impact on the environment.

Understanding Biodegradable and Compostable Materials

Biodegradable and compostable materials are designed to break down naturally over time, returning to the earth without leaving behind harmful residues. While both terms relate to the ability of materials to degrade, they differ in their degradation processes:

Biodegradable: Materials break down through natural processes by microorganisms, typically within a reasonable timeframe.

Compostable: Materials degrade under specific conditions (e.g., industrial composting facilities) into organic matter, leaving behind no toxic residue and contributing valuable nutrients to the soil.

Benefits of Biodegradable and Compostable Materials in Sandwich Wrap Packaging

1. Environmental Impact

Reduced Plastic Dependency

Alternative to Plastics: Biodegradable materials offer a sustainable alternative to traditional plastics, which often contribute to environmental pollution and marine debris.

Carbon Footprint: Using renewable resources like plant-based polymers reduces carbon emissions compared to petroleum-based plastics, contributing to climate change mitigation.

2. Resource Efficiency

Renewable Resources

Sustainable Sourcing: Materials such as PLA (Polylactic Acid), derived from corn starch or sugarcane, are renewable and support agricultural economies without depleting finite fossil fuel resources.

Closed-Loop Systems: Biodegradable materials can be integrated into closed-loop systems where they are recycled or composted, minimizing waste and promoting resource efficiency.

3. End-of-Life Disposal

Biodegradation and Composting

Natural Breakdown: Biodegradable materials naturally degrade into harmless compounds when exposed to moisture, heat, and microorganisms in various environments.

Composting: Compostable materials undergo controlled decomposition in composting facilities, generating nutrient-rich compost that improves soil health and fertility.

4. Consumer Perception and Market Demand

Green Consumerism

Preference for Sustainability: Increasing consumer awareness and demand for eco-friendly products drive businesses to adopt biodegradable and compostable packaging solutions.

Brand Loyalty: Brands that prioritize environmental stewardship by using sustainable materials can enhance brand reputation and appeal to environmentally conscious consumers.

Challenges and Considerations

1. Performance and Durability

Balancing Strength and Sustainability

Material Integrity: Ensuring biodegradable wraps maintain adequate strength and barrier properties equivalent to conventional plastics is crucial for food safety and product integrity.

Innovative Coatings: Advances in biodegradable coatings enhance moisture and grease resistance, extending the functionality and usability of biodegradable sandwich wraps.

2. Regulatory Standards and Certification

Ensuring Compliance

Certifications: Products certified by reputable organizations like BPI (Biodegradable Products Institute) or OK Compost HOME meet stringent standards for biodegradability and compostability, ensuring they are safe for the environment and consumers.

The adoption of biodegradable and compostable materials in sandwich wrap packaging marks a significant step towards reducing the environmental footprint of food packaging. By embracing these sustainable alternatives, manufacturers not only contribute to waste reduction and resource conservation but also align themselves with evolving consumer preferences for eco-friendly products. As innovation continues to drive the development of biodegradable materials and technologies, the future looks promising for sustainable packaging solutions that prioritize environmental stewardship without compromising on performance. Through collaboration, education, and commitment to sustainability, the food packaging industry can lead the way towards a more sustainable and resilient global economy.

How easy is it to use and secure different types of sandwich wraps?

Plastic Wrap: Plastic wrap is flexible and conforms well to sandwich shapes, making it relatively easy to use. However, it can sometimes be tricky to handle as it may stick to itself or tear if not used carefully. Securing plastic wrap usually involves pulling tightly and pressing it against itself or using a cutter to tear the wrap. It's effective at creating a seal that helps keep sandwiches fresh by preventing air from getting in.

Wax Paper: Wax paper is easy to handle and doesn't stick to itself like plastic wrap can. It's typically secured with a piece of tape or by folding the edges tightly. While it's straightforward to use, the seal may not be as airtight as with other materials, potentially allowing some air to enter over time.

Aluminum Foil: Aluminum foil is versatile and easy to shape around sandwiches, especially useful for hot sandwiches as it retains heat well. It's sealed by crimping the edges tightly. However, foil can tear if not handled carefully, and it may not be as convenient for multiple openings and closings due to the need to re-crimp or fold.

Reusable Fabric Wraps: These wraps, often coated with beeswax or another natural material, are shaped around sandwiches using the warmth of your hands. They are secured by folding or pressing the edges together. While they are eco-friendly and reusable, they may require extra care to ensure a tight seal, which can impact their effectiveness in keeping sandwiches fresh over extended periods.

Reusable Plastic/Silicone Bags: These bags are very user-friendly with a zip or press-seal closure that makes them quick and easy to open and close. They provide a reliable seal, preventing air from entering and helping to maintain freshness. Cleaning after each use is necessary, but they are durable for repeated use.

Parchment Paper: Parchment paper is easy to handle and doesn't stick to food or itself. It's typically secured with tape or by folding the ends tightly. While it's simple to use, it may not provide as tight a seal as other materials, which could affect how long the sandwich stays fresh.

Cling Film: Cling film is stretchable and adheres tightly to surfaces, making it effective at creating a seal. It's convenient for wrapping sandwiches quickly but can be tricky to handle as it often sticks to itself. Careful handling is needed to prevent tearing or wrinkling that could compromise the seal over time.

Each type of sandwich wrap has its advantages and considerations regarding ease of use and securing. The choice depends on factors like convenience, environmental impact, and how long the sandwich needs to stay fresh.