Understanding Sandwich Wrap Paper and Its Importance Sandwich wrap paper is a fundamental component in the food service industry, designed to protect,...

READ MOREAll

Baking Paper

Greaseproof Paper

Wax Paper

Parchment Paper

Cooking Sheet Paper

Steaming Paper

Hamburger Wrap

Sandwich Wrap

Pan Liner

Candy Wrap

Air Fryer Paper

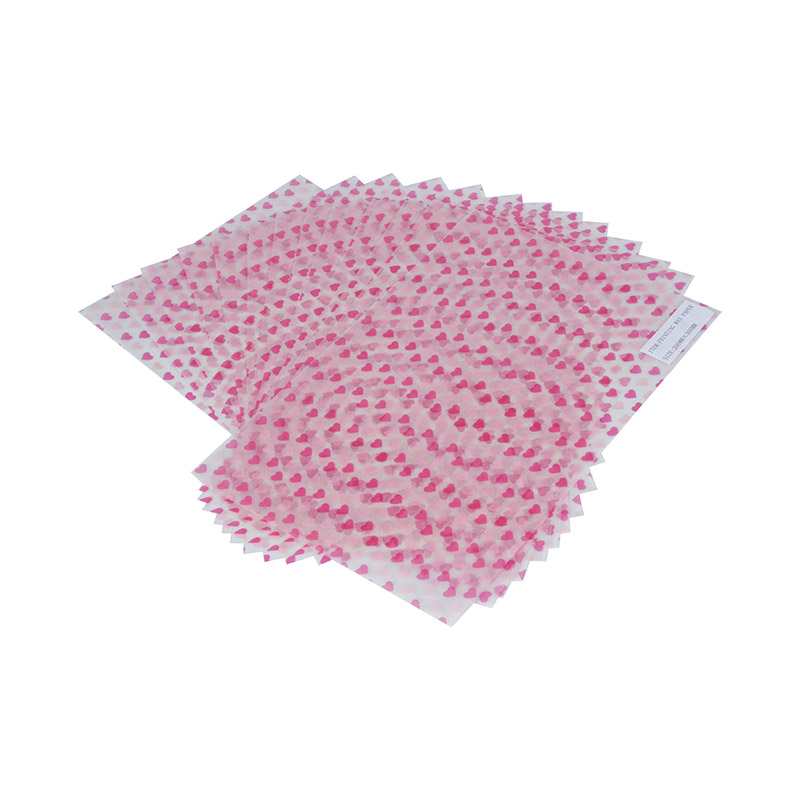

Brand Name: YISAKA Coating Material Wax Coating Side Single Side Compatible Printing Letterpress pri...

Brand Name: YISAKA Coating Material Wax Coating Side Single Side Compatible Printing Letterpress pri...

Brand Name: YISAKA Coating Material Wax Coating Side Single Side Compatible Printing Letterpress pri...

Brand Name: YISAKA Coating Material Wax Coating Side Single Side Compatible Printing Letterpress pri...

Understanding Sandwich Wrap Paper and Its Importance Sandwich wrap paper is a fundamental component in the food service industry, designed to protect,...

READ MOREThe Functional Science of Grease-Resistant Barriers Hamburger wrapping paper serves a much more technical purpose than simply acting as a decorative s...

READ MOREThe Essential Role of Steamer Paper in Modern Cooking Steamer paper, often referred to as perforated parchment liners, serves as a critical barrier be...

READ MOREThe Critical Role of Steamer Paper in Modern Cooking Steamer paper, often referred to as perforated parchment paper, is an indispensable tool for anyo...

READ MOREHow the quality of coating application affects the non-stick properties of wax paper?

Wax paper is an indispensable tool in both domestic and industrial kitchens, renowned for its non-stick properties that simplify food preparation and cleanup. The effectiveness of wax paper largely depends on the quality of the wax coating applied to its surface. This article explores how the quality of the coating application influences the non-stick properties of wax paper and why achieving a high-quality coating is crucial for optimal performance.

Understanding Wax Paper Coating

Wax paper is typically coated with a layer of wax, such as paraffin, soy, or beeswax, to create a non-stick surface. The wax coating acts as a barrier between the food and the paper, preventing food from adhering to the paper during use. The effectiveness of this barrier depends on several factors related to the coating application process.

Factors Affecting Coating Quality

Type and Quality of Wax

Wax Selection:

Paraffin Wax: Widely used for its cost-effectiveness and good non-stick properties. It provides a smooth, even coating that resists sticking.

Soy Wax: An eco-friendly alternative that also offers effective non-stick capabilities. It is biodegradable and preferred for environmentally conscious applications.

Beeswax: Known for its excellent non-stick properties and natural composition. It is more expensive but provides a high-quality, durable coating.

Wax Purity:

Importance: The purity of the wax affects its performance. Impurities in the wax can lead to inconsistent coating and reduced non-stick properties.

Refinement Process: High-quality wax is typically refined to remove impurities, ensuring a smoother and more uniform coating application.

The quality of the coating application is a critical factor in determining the non-stick properties of wax paper. Uniform application, optimal thickness, strong adhesion, and the choice of wax all play vital roles in ensuring that the paper performs effectively. By focusing on these factors and employing advanced technologies and rigorous quality control measures, manufacturers can produce high-quality wax paper that meets the needs of both domestic and industrial users. High-quality wax paper not only enhances convenience in food preparation and storage but also contributes to better food presentation and reduced waste.

What is the effect of coating process on the moisture penetration of wax paper?

The coating process significantly influences the moisture penetration properties of wax paper. Here's a detailed look at how different aspects of the coating process affect moisture resistance:

Wax Coating: Traditional wax paper uses paraffin or microcrystalline waxes. Wax provides a good moisture barrier by filling in the paper's pores, creating a hydrophobic layer that repels water.

Polyethylene (PE) Coating: Some modern wax papers may use PE instead of wax. PE coatings offer excellent moisture barriers and are often more consistent in performance compared to wax.

Other Coatings: Materials like silicone or polymer blends can also be used to enhance moisture resistance and provide additional benefits like grease resistance.

Increased Thickness: A thicker coating generally provides better moisture resistance because it creates a more substantial barrier that is harder for water molecules to penetrate.

Uniformity: Uniform thickness across the paper ensures consistent performance. Variations in thickness can lead to weak spots where moisture can penetrate more easily.

Dipping: This method involves immersing the paper into the wax or coating material. It ensures a thorough coating but may lead to excess material on the paper.

Spraying: Spraying can provide a more controlled and even coating but may require multiple applications to achieve the desired thickness.

Extrusion Coating: This is common for polymer coatings like PE. It provides a smooth and uniform layer, improving the moisture barrier's effectiveness.

Calendaring: Involves pressing the coated paper between rollers to achieve a uniform coating thickness and smooth surface, which enhances moisture resistance.

Proper Curing: For coatings that require curing, such as certain polymers, proper curing ensures the coating adheres well to the paper and fully develops its moisture-resistant properties.

Incomplete Drying: If the coating is not properly dried, it can lead to defects and areas where moisture can penetrate more easily.

Surface Smoothness: A smoother surface reduces the number of pathways for moisture to enter the paper.

Surface Energy: Treatments that alter the surface energy of the paper can improve the coating’s adhesion, enhancing its moisture barrier properties.

Additives: Additives in the coating formulation can improve moisture resistance. For example, hydrophobic agents can make the coating repel water more effectively.

Plasticizers and Stabilizers: These can affect the flexibility and durability of the coating, which in turn impacts moisture resistance, especially under varying temperature and humidity conditions.

The coating process is crucial in determining the moisture penetration properties of wax paper. Factors such as the type of coating material, application method, thickness, and surface treatment all play significant roles in enhancing the paper's resistance to moisture. Proper control and optimization of these variables ensure that the wax paper performs effectively in preventing moisture penetration.